Life’s a beach when you automate print

When is an automated workflow demonstration not really an automated workflow demonstration? When you’re only getting to see a small part of the workflow.

And that’s something that’s frustrated us for a while – what’s the point in showing off our platform at trade shows, if the printer is seeing it in isolation?

A completely automated workflow

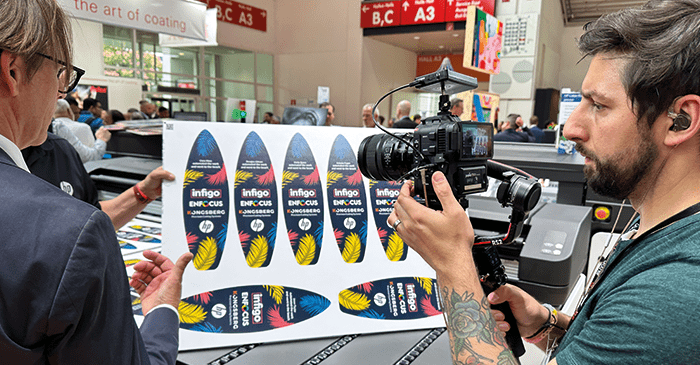

That’s why this year, we, along with our friends and partners at Enfocus, Kongsberg Precision Cutting Systems and HP, went to great lengths to show off not only how easy it is to use our software to create individually branded storefronts, with a powerful editor, that enables you to personalise at scale; but to also show how, when integrated with other platforms, Infigo’s web-to-print solution is essential to creating a completely automated workflow, from start to finish.

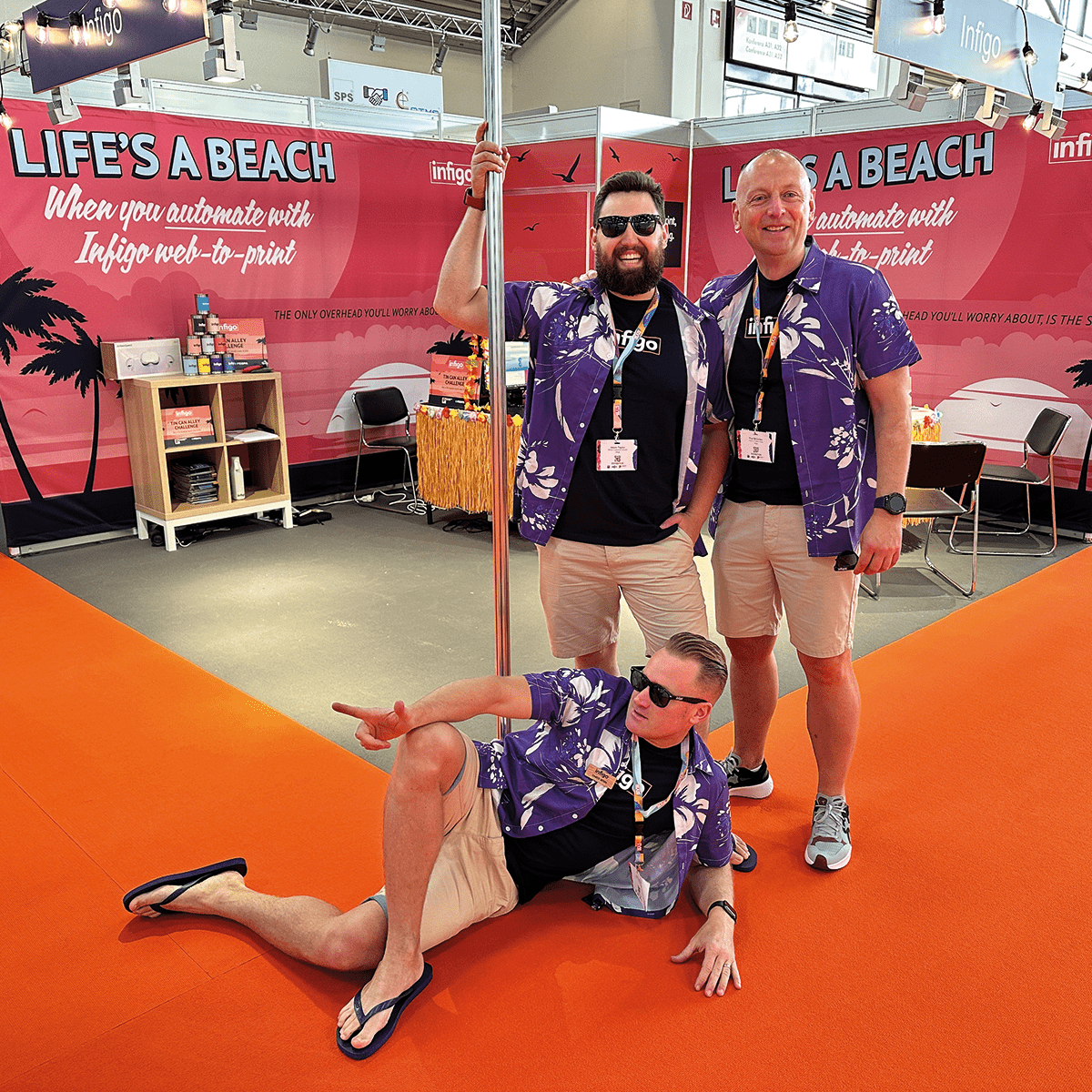

This is how we found ourselves hosting a laid-back beach party in Munich, Germany at The Personalisation Experience, co-hosted with FESPA’s Global Print and European Sign Expo 2023. That’s right; we held a beach party in one of the most landlocked cities in the world – you can never accuse us of not being creative!